ABOUT US

Our Company

Kinetron Asia Sdn Bhd, Malaysia was established in 2001 as material handling system manufacturer. We seek to establish ourselves as one of the leaders in providing a solution to the material handling system. We principally involve in the design, manufacture, installation and commissioning of turn-key system as well as maintenance services.

Our Quality Policy

Kinetron committed to meet customer satisfaction in terms of cost effective solutions, quality and delivery. We also committed to comply with customer requirement and to continually improve the effectiveness of quality management system.

License & Certificate

- LMW (License Manufacturing Warehouse)

- Manufacturing License by MIDA

- ISO9001 (Quality)

Core Business

Our core business includes the following:

- Material Handling System for Electronic, Manufacturing, Automobiles, Food & Beverage and Warehouse Automation.

- PCB Handling Equipment for PCBA Industry.

- Original Design Manufacturing (ODM) for Other Brand Names.

- Original Equipment Manufacturing (OEM) for Capital Equipment Manufacturers.

Core Competencies

- Research and Development

- Manufacturing Know How

- Supply Chain Management

- Enterprise Resource Planning

- Quality Management System

- Extensive Service Support

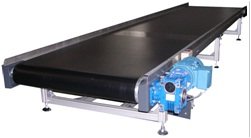

Conveyor

Standard Belt Conveyor (BC105)

Supermini Belt Conveyor

MD Belt Conveyor

Cleated Belt Conveyor

Wire Mesh Belt Conveyor

Curve Belt Conveyor

Assembly Twin Belt Conveyor

Material Handing Equipment

Material Handling Equipment (MHE) refers to the tools, vehicles, storage units, appliances, and accessories used to move, store, control, and protect materials during manufacturing, warehousing, distribution, consumption, and disposal.

Chain/Timing Belt Driven Roller Conveyor

Zero Pressure Accumulation Conveyor

Motorized rollers (MDR) are conveyor rollers with their own internal motors.Each motor roller controls a small zone of free-turning rollers.This inherently modular design makes designing and building a Zero Pressure Accumulation conveyor systems faster and easier than coinventional conveyor system.

Benefits

- Fats & Easy installation

- Flexible to Meet Changing Needs

- Low Maintenance Cost

- Quiet

- Safe

Pulse Roller Driven Conveyor

Assembly Twin Belt Conveyor

Gravity/Free Roller Conveyor

Ball Transfer/Wheel Conveyor

Driven Turntable Conveyor

It combines a conveyor (like rollers or chains) mounted on a rotating turntable platform. The platform is motor-driven and can rotate to redirect the load to a new conveyor path or station.

Heavy-duty driven roller Conveyor

A Heavy-Duty Driven Roller Conveyor is an industrial-grade conveyor system designed to move heavy loads using powered rollers. Unlike gravity conveyors (which rely on slope), these rollers are motor-driven to actively transport materials—even large, bulky, or palletized items—along a flat or inclined path.

Free-Flow Chain Conveyor

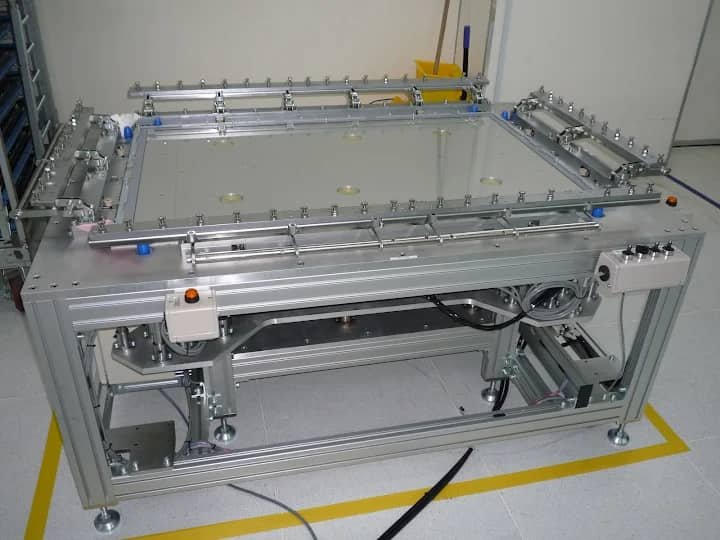

The free-flow conveyor system is designed to be very versatile and flexible. Constructed from steadily and anoidized aluminium extrusion. The standardised design, is made to last and can be easily fix into existing and mass production line. It is applicable in the below industires :-

- TV assembly line

- Computer assembly line

- Audio & video assembly line

- Printer assembly line

- Air-conditioner assembly line

- Micro wave assembly line

Palletised Chain Driven Conveyor

Palletised chain conveyors are heavy unit load conveyor systems that have the durability and versatility to work efficiently in a wide variety of applications and industries. Whether application for transport,stop and accumulate, reorientate or stage loads.

Table Top/ Slat Chain Conveyor

The table top chain conveyor is mainly used in conveyor material in bottle and can. It is designed in either stainless steel or mild steel structure. The table top chain thermoplastic and SUS chain is mainly used in food industry. The accumulation and speed acceleration function is made standard and further enhanced by side guide. PLC control & etc; for better conveying flow of material.

Manual Insert Chain Conveyor (SMT)

The Manual Insert Chain conveyor is used to convey PCB's before wave soldering machine.The operator will sit in front sides and insert the through-hole components, capacitors, resistors etc, into the PCB. The conveyor come with flexible adjustable width according to PCB's required width.

automatic assembly line for front-loading washing machines

An automatic assembly line for front-loading washing machines is a highly integrated manufacturing system designed to automate the production, assembly, and testing of front-load washing machines. It improves efficiency, consistency, and reduces labor reliance.

conveyor system

A conveyor system is a mechanical handling system used to transport materials or products from one location to another within a facility. It is essential in manufacturing, warehousing, packaging, and logistics for improving efficiency, accuracy, and safety.

AUTOMATIC MAGAZINE LOADER

- Suitable For SMT And Insertion Lines

- Upper And Lower Clamps For Positive Magazine Location

- Power Failure and Abnormal Codition Recovery

- Regulated Pusher Pressure

- Programmable Login Control

- SMEMA Interface

- Touch Screen Of Operating Panel (Option)

- In HighSpeed Model With Shorter Magazine Change Over Time Of about 14 sec (Option)

AUTOMATIC MAGAZINE UNLOADER

- Suitable For SMT And Insertion Lines

- Upper And Lower Clamps For Positive Magazine Location

- Power Failure and Abnormal Codition Recovery

- Minimum Cost And Size By Unification Buffer With Body

- Programmable Login Control

- SMEMA Interface

- Touch Screen Of Operating Panel (Option)

- Fast Magazine Change Time (Option)

Bare Board Loader

- Suitable For SMT And Insertion Lines

- High Suction Force With Flexible Suction Pads

- Front Loading of Bare Boards

- Constant Board Loading Cycle Time

- Large PCB Stock Capacity

- Programmable Logic Control

- SMEMA Interface

- Touch Screen Of Operation Panel (Option)

Manual Insert Chain Conveyor (SMT)

- Suitable For SMT And Insertion Lines

- Regulated Pusher Pressure

- Ability To Perform:

- FIFO Operation

- LIFO Operation

- Pass Through Operation

- Loader Operation (Operation)

- Unloader Operation (Operation)

- Reject Stock Operation (Operation)

- Programmable Logic Control

- SMEMA Interface

- Touch Screen Of Operation Panel (Option)

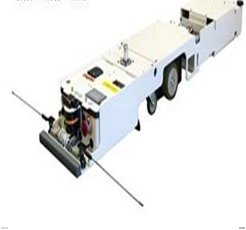

Telescopic Gate Conveyor

- Fully Automatic Operation

- Enhanced Safely Design

- Walkway "Normaly OPen"

- 600mm Walkway

- Programmable Logic Control

- SMEMA Interface

- Smooth And Quiet Extent And Vetract Operation

- Touch Screen of Operation Panel (Option)

Gate/Passage Conveyor

- Manual Open The Passageway

- Enhanced Safely Design

- 500mm Gateway

- Easy Width Adjustment

- Programmable Logic Control

- SMEMA Interface

- Automaticaly Adjust To Open The Gateway (Option)

Gate/Passage Conveyor

- In-Line, Redirecting PCB Flow As Required By Limitation in Floor Space or Process Requirement

- Fast Cycle Time

- Programmable Logic Control

- SMEMA Interface

- Smooth And Quiet Extent And Vetract Operatio

PCB Inverter Unit

- For Double Sided Placement Of Components On PCB

- Using Air Cylinder For Stable Revolution

- High Speed

- Easy Width Adjustment

- Enhanced Safely Design

- Programmable Logic Control

- SMEMA Interface

Work Station Unit

- Offers Buffer Work Operation

- Flexible Operation (With Bypass Mode)

- Easy Width Adjustment

- Adjustable Speed

- Easy Setup

- Programmable Logic Control

- SMEMA Interface

Link Conveyor

- Suitable For SMT Line

- Flexible Operation (With Bypass Mode)

- Easy Width Adjustment

- Adjustable Speed

- Easy Setup

- Programmable Logic Control

- SMEMA Interface

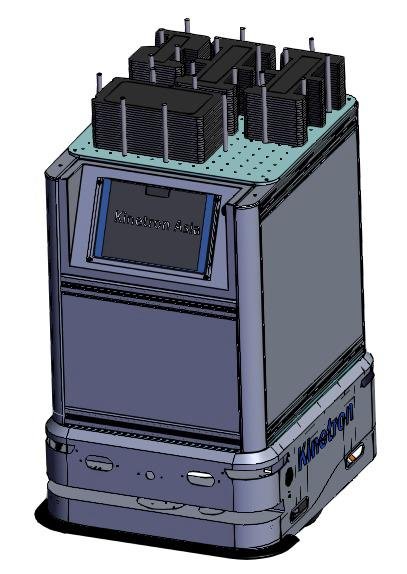

Autonomous Mobile Robot (AMR)

An Autonomous Mobile Robot (AMR) is a type of robot that moves intelligently and independently through a space without direct human control or physical guides like tracks or magnetic strips. AMRs use sensors, cameras, AI algorithms, and maps to understand their environment and navigate dynamically.

OEM/ODM Product

Corporated as OEM to world leading company for laser marking machine manufacturer and In-Line Circuit Tester unit.

Hi-Speed Lifter/Goods Lifter

Kinetron designed various types of lifter for different market needs. They are air lifter, high speed lifter, compact lifter and etc. Each of this lifter is commensurate with different type of transfer available for selection; such as ywin belt, pulse roller & PVC chain transfer. It is used mainly to convey product at different floor/ height level vertically and is applicable in many fields includes TV, computer, handphone and electronic assembly line.

Telescopic Gate Conveyor

it is extendable & retrectable conveyor. It is hand adjustable to suit existing requirements without the need of any special tools. It is ideally used for loading/ unloading areas where space is limited, also cab be use for passage way for operator. It is labour effective as for no extra workforce is needed.

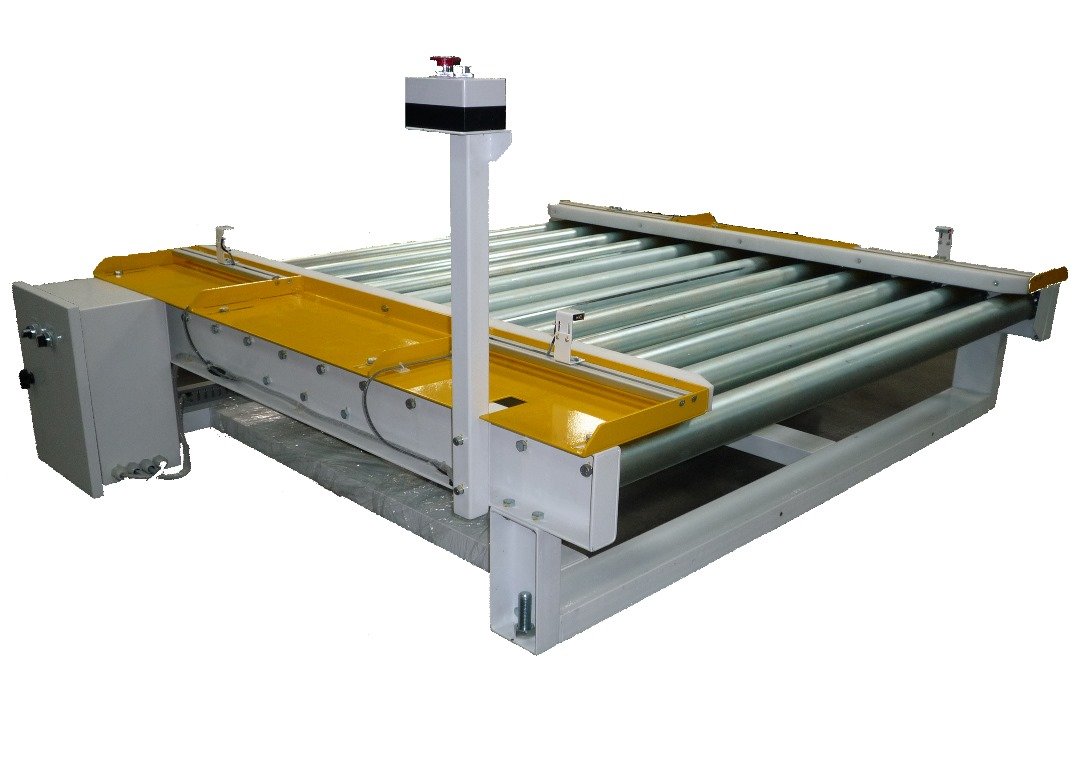

Roller Bed Belt Conveyor

The roller bed belt conveyor is widely used in most of the industries. This model is applied in the assembly line, packaging sections, inspection and inter-department transference. The roller bed design reduces belt friction and provided greater capacity. Both the horizontal and inclined model are available for selection, in order to suit the different market conditions.

Inspection Machine

Customised Inspection Machine

Press Machine

Customised Press Machine

Jig & Fixtures

Customised Inspection/Assembly Jig & Fixtures

Specialized industrial machine

Customised Specialized industrial machine

Specialized EDM

Customised EDM

Integrated Belt Sortation (Vertical/Horizontal)

Our high rate sortation systems feature an advanced controls system that includes visualization and function control of the merge,induct and sortation subsystems.The control system is accessed through the IT portal,a web-enabled browser based interface for all Director IT Warehouse Management system (WMS).These sortationsystems provide advanced levels of user control for management of merge to sortation hardware,visualization,diagnostics, and performance monitoring. The sortation systems are used by leading general marchandise retailers and distributors,3PL,catalog,hardware, parcel and freight, and other companies requiring high speed, realible product and package sortation.

Vacuum Lifter (Overhead Crane System and Jib Cranes)

Vacuum Lifter is design proven system meeting the highest standards of functionality and safety. The suction foot holds the load securely in place until it has reached the floor. The air is channelled through a filter and air hose from a lifting tube fitted with a suction foot. The lifting tube is suspended on a swivel and can be operated in 360 degrees.The vacuum inside the lifting tube is regulated with a control handle. Power failure do not cause any safety issues. In the event of a black out, a safety vaive shuts down and the load is lowered to the floor gently and under complete control.

Battery Operated Lifter

Protema electric lifts are very versatile and makes lifting and moving goods easier in all types of inductries.The Protema lifters are battery operated and designed with a robust chassis and reliable electronics.These roll lifters are extremely light weight with a built-in charger, easy to use for all operators. With Protema lifts, difficult and potentially harmful lifting can be avoided and an ergonomic method of moving goods can be achieved.

Manipulator

The Manipulator is a good working assistant for the operator who can work quickly, with precision and without any effort, in excellent ergonomic and safety conditions. Equipped with special gripping tools, it is particularly suitable to manually handle loads in a weighless condition in any condition.

AGV (Automated Guided Vehicle)

The Manipulator is a good working assistant for the operator who can work quickly, with precision and without any effort, in excellent ergonomic and safety conditions. Equipped with special gripping tools, it is particularly suitable to manually handle loads in a weighless condition in any condition.

Industrial Robot

The industrial robots are used in a number of application areas such as material handling,loading and unloading of machines, palletizing and depalletizing,spot and arc welding.They are used in a number of large companies,predominantly in the automotive industry but also in other industries such as the aerospace industry.

Dekstop & Dispensing Robot

Automated desktop dispensing robot offer reliable operation with excellent repeatability for precise adhesive application, sealant application and lubrication application in many assembly and manufacturing processes.

Articulated Jib Crane

An Articulated Jib Crane is a type of flexible lifting device that features two or more swivel arms (joints), allowing it to reach around obstacles and into tight or complex workspaces. It is designed for precise, localized lifting and placement of materials, often in assembly lines, workshops, and workstations.

Focused-Ultrasonicator

A Focused-Ultrasonicator is a high-precision instrument used primarily for sample preparation in biological, chemical, and material science labs. It uses focused ultrasonic energy to break, shear, or mix materials at a microscopic level. The most common application is in DNA/RNA shearing, cell lysis, emulsification, and nanoparticle dispersion.

Gallery

company profile

project reference

Contact Us

Our Locations

Main Office – Johor

16, Jln Gemilang 10, Taman Perindustrian Cemerlang, 81800 Ulu Tiram, Johor Darul Ta’zim

- jbsales@kinetronasia.com

- +60 127126701

Sales & Service Office – Penang

No. 25, Jalan Perai Jaya 5,

Bandar Perai Jaya,

13700 Seberang Perai Tengah,

Penang, Malaysia

- pgsales@kinetronasia.com

- +60 12-4770577